Overview

By integrating the power pack into the winch, not only does it save space, but it is also easy to install. The power unit consist of two electric motors of 22 kW giving it the required redundancy. In case of breakdown, the winch can be operated on one motor making the whole setup very reliable and safe to work with.

Contant Tension

The constant tension (CT) mode keeps the umbilical continuously in the correct position. With the Hägglunds direct drive the winch can be controlled very accurate, resulting in a highly accurate CT. The setpoint of the CT-mode can be set upon 40 kg accuracy.

Features

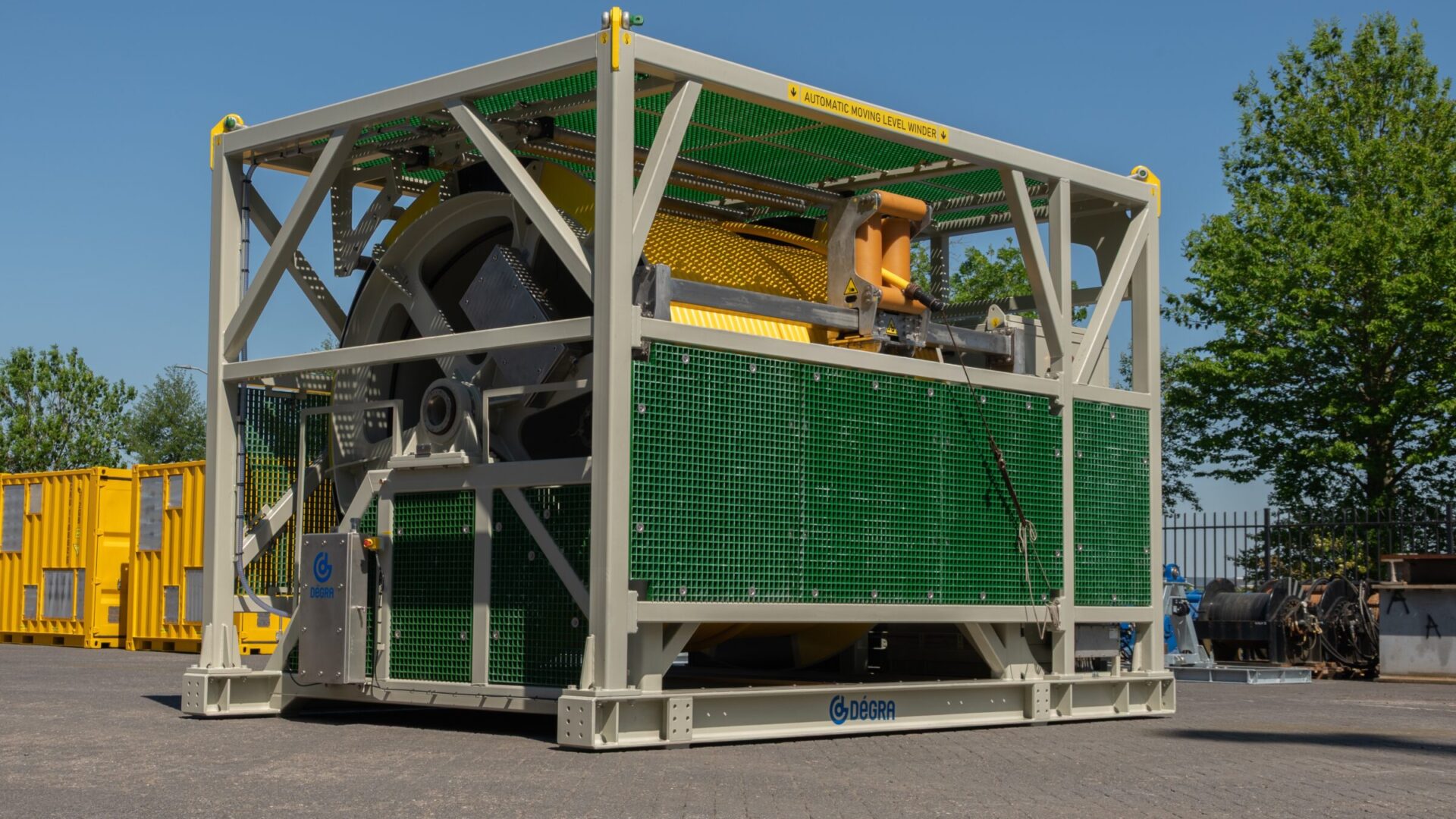

- Hydraulic operated level winder: With a Canbus encoder on the main hydraulic motor and on the shaft of the level winder, the level winder can be controlled automatically. It can also be adjusted to the diameter of the umbilical.

- Suitable for an extra large slip ring

- Umbilical cooling system: With drip tray to reuse the fresh water used for the cooling.

Technical Facts

Line pull

Capacity

Speed

Render Speed

Power

Control System

The winch and EHPU can be controlled from the operating panel on the power pack. It is also possible to use the controls installed in the dedicated operator container. For this, the existing control panel supplied by the customer was used and modified.

The control system is designed to be as intuitive as possible. The screen found at both control locations provides the operator with insight into the system’s performance. For example, you can see what the force on the umbilical is and what the output length is. You can also use the display to alter the levelwinder settings.